|

Composiclean, LLC - Product Testing Phase #1

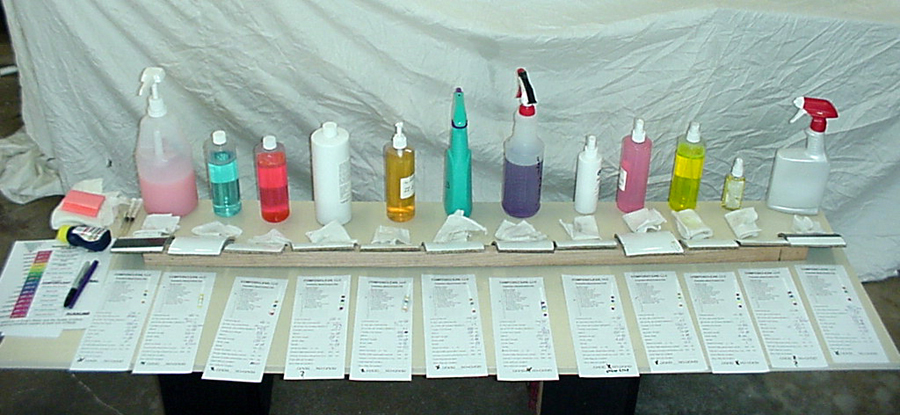

Photo: One of many composite test tables. (March

06)

We took what was left of a composite aircraft fuselage

(w/Airex® foam) that was used for

structural testing, cut it up into little pieces and went to work. We used all the proprietary blends we ordered from around

the country as well as everything we could find around the shop to clean, detail and soak the pieces. We looked at things

like, is it a concentrate? If yes, what are the dilution ratios and the pH levels of usable product? We answered the questions,

is it considered neutral? Is it a spray or bucket wash, how long did the piece soak, was it rinsed, how effective is it on

a scale of 1 to 10 (basically, did we like it), was deterioration noticed on the foam core. On aluminum parts, was there noticeable

galvanic corrosion.

Our proprietary blends faired well, as we expected.

Our design criteria specified so many critical points, they couldn’t help but be right. Some of the products we had

in the shop (the big names you can buy around town) did not work as well. In our search, we came

up with Neutral pH products where needed and safe levels above and below for all other areas of cleaning. On this web site

you will find all the right products to clean and detail your aircraft as well as the instructions to use our products correctly.

Composiclean,

LLC - Product Testing Phase #2

(July 06)

After phase #1 composite/Airex® foam tests with our products as well as others where complete

we approved the recipes for the products to provide through Composiclean™. Our liquid products (at this time) include

seven different bottled products & two aerosols (these have no cfc’s which deplete the ozone layer).

Phase #2 testing is in process

at this time.

The short-term tests of phase #2 are complete. As we

expected, our neutral pH products show zero effects on Rohacell®

foam after being literally soaked in the solutions for hours.

We will provide results of the long term soak as well

as documented photos in early August.

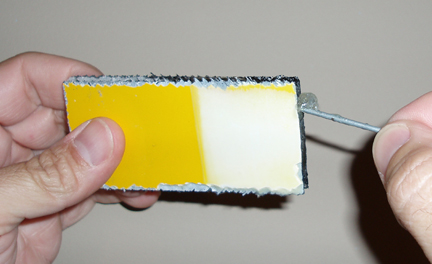

In the above

photo, on the far right is a big name product (NOT Composiclean) we’ve used for a long time. It is a high alkaline

product with an MSDS reported pH 13. This product works very well on engine grease and on wheels for break dust,

but, keep it away from composite foams. This high alkaline product will begin to dissolve many of the commonly used

foams within minutes. Within 3 hours of being soaked, the foam is about 40% dissolved. After 8 hours it is totally destroyed (see photos 9 & 10 below).

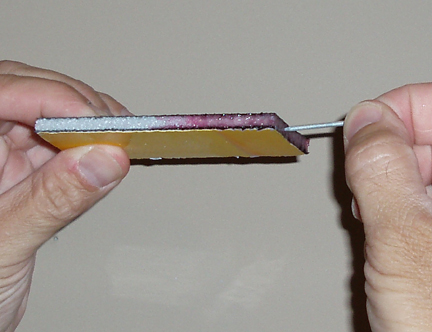

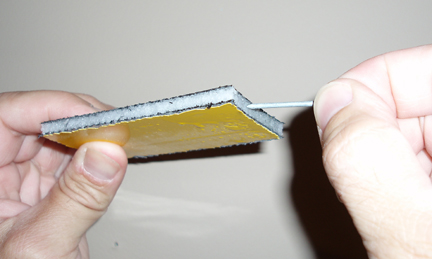

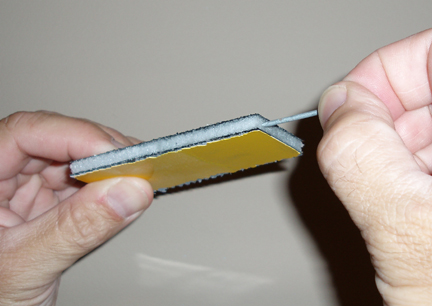

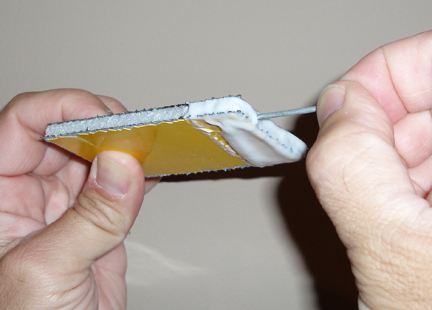

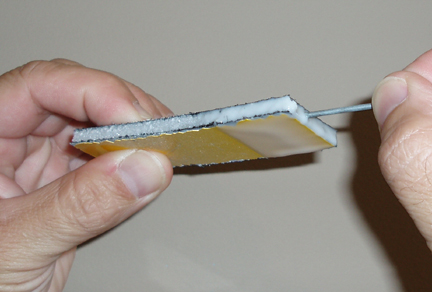

The photos below are samples of an aircraft composite

sandwich (Rohacell®, carbon fiber &

gel coat) after being soaked for 8 hours in the named product. For each product we used a small pointed finish nail to compare densities between the soaked area and

the dry area.

#1) Composiclean™

Bucket-Wash™ Straight Concentrate. - Zero effect / 8hrs soaking.

#2) Composiclean™ Bucket-Wash™ Dilution - Zero effect / 8hrs soaking.

#3) Composiclean™ Super Spray-Wax™ - Zero

effect / 8hrs soaking.

#4)

Composiclean™ Leather

Cleaner & Conditioner - Zero effect / 8hrs soaking.

#5)

Composiclean™ Tire Dressing - Zero effect / 8hrs soaking.

#6) Composiclean™ Vinyl Cleaner - Dissolving

effect at contact area (approx 1/8’ soft) 8hrs soaking.

#7) Composiclean™ Vinyl Dressing - Zero effect

/ 8hrs soaking.

#8) Composiclean™

Multi Purpose Cleaner (MPC) - Dissolving effect at contact area (approx 1/8’ soft). 8hrs soaking.

#9) Our sample #9 photo #1 Example of a common of the

shelf alkaline cleaner / degreaser (note the total deterioration and deformation of structure. The alkalinity is also attacking the gel coat. 8hrs soaking.

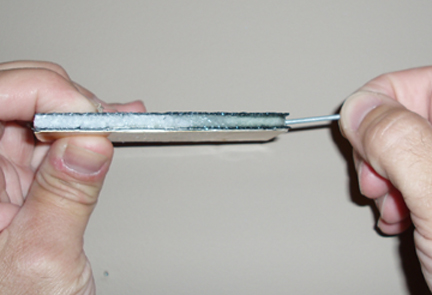

#10) Our

sample #9 photo #2 Example of a common of the shelf alkaline cleaner / degreaser, note the total deterioration and deformation

of structure. The foam is soft and collapsing

throughout the 1.5 inch piece. 8hrs soaking

All of our aqueous solutions have the proper MSDS

(Manufacturer Safety Data Sheets)

and are registered with poison control.

|